A Solid Future

Solid State Batteries - Are they possible?

Those in the battery industry have continued to push R&D efforts to maximize battery performance. Reports have been surfacing that the industry could be preparing to make a quantum leap forward toward commercializing solid state batteries.

Traditional (wet) Li-ion Batteries

Traditional Li-ion batteries contain liquid electrolyte, which typically consists of LiPF6 (lithium hexafluorophosphate) dissolved in carbonate (ethyl, diethyl, dimethyl, propylene) solvents. These batteries have their limitations on the energy that they can produce and have the potential of undergoing thermal runaway, which usually leads to a fire.

Solid State

Take the above mental model and then remove the solvent/electrolyte that is suspending and facilitating lithium ion transfer.

Solid state batteries have a solid, but flexible polymer or ceramic separator that makes the battery more compact. The material is also much less likely to spontaneously combust making the battery safer and more stable. In fact, a solid state battery company, QuantumScape, shared some DSC (differential scanning calorimetry) data displaying the thermal stability of their separator technology.

Lithium and liquid electrolyte experiences a strong exothermic energy release around 180C, while lithium and the ceramic separator result in a slightly endothermic (energy absorbing) reaction. The former scenario typically results in a fire, while the endothermic reaction suggests that the Li is absorbing energy in order to melt without a subsequent exothermic explosion.

Why Solid State?

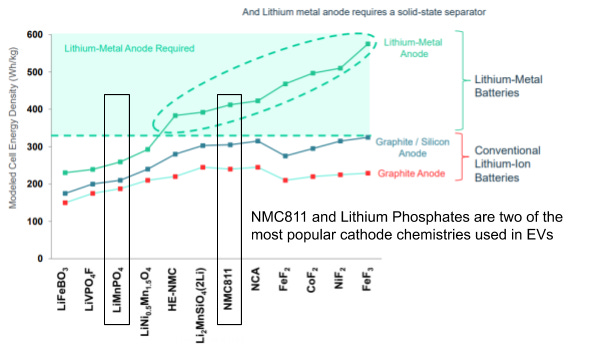

Traditional Li-ion batteries also have limitations on energy density because of silicon expansion. Silicon is added to graphite anodes to increase the capacity of the cell. Unfortunately, Si swells during the battery charging and discharging process causing the anode to lose structural integrity. The swelling and contraction over time causes the binding polymer in the anode to lose strength, and ultimately lead to decreased cycling performance over time. The graph below shows the benefit of adding silicon to the anode and that ~320 Wh/kg is the maximum achievable energy density for today’s traditional battery. Advancing to Li-metal/solid state batteries will be the only way to make the jump to >400 Wh/kg.

Solid state batteries have been under development for about a decade. While safety is key, experts are also showing how the technology can enable lower costs, higher energy density, and higher ionic conductivity. The specific capacity of lithium is about 3860 mA/g, while traditional graphite anode is about 372 mA/g, so being able to replace graphite is a big deal. You could make a battery with Li-anode that has 1/10 the mass of a graphite anode, yet produces a similar amount of energy.

Performance Benefits

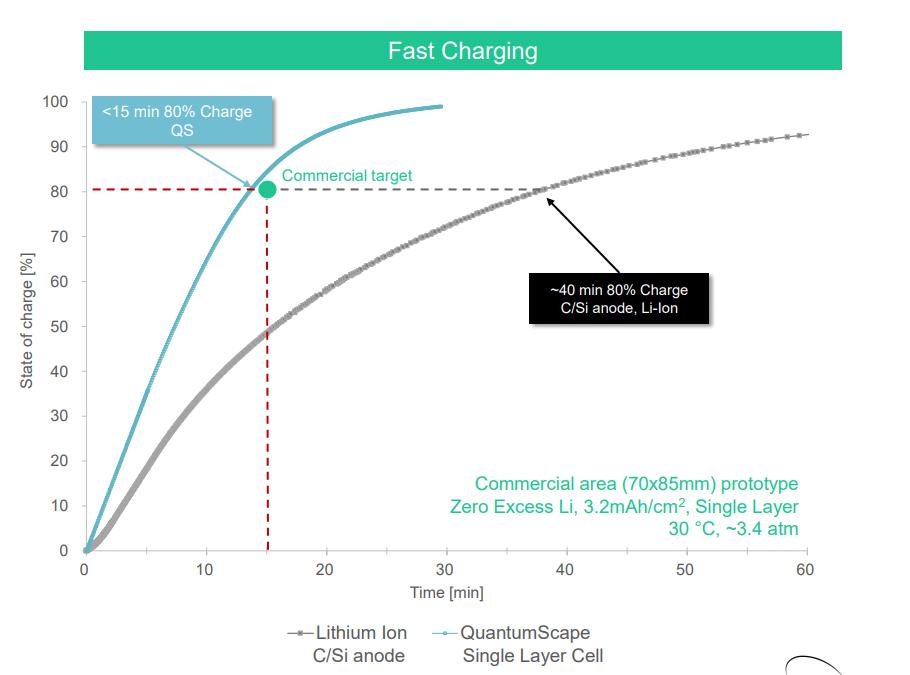

A battery that lasts longer is the goal. Solid state batteries use pure lithium as the anode, and this provides a faster exchange between electrodes. This corresponds to a higher rate of charge and discharge, which is highly desirable especially when we think about charging today’s electric vehicles. In the image below, QuantumScape’s battery charges to 80% state of charge (SoC) in less than 15 minutes which is significantly better than a graphite/Si anode Li-ion battery.

This is superior to traditional wet Li-ion batteries, because typically higher charge rates facilitate dendrite growth and potential cell failure.

But at what cost?

Cost and scalability are also of utmost importance, because solid state is battling the rapid advancement of companies that are producing traditional, wet Li-ion batteries. Each year manufacturers are making incremental improvements to optimize and reduce the cost of premier batteries being produced by CATL, LG Chem, and Tesla. Below is a report shared by Exawatt showing cost modeling of the potential cost reductions that solid state could enable.

Today the average Li-ion battery cost is about $110/kWh with forecasts pushing to break below the $100/kWh barrier. By 2025 models are showing that with traditional technology and manufacturing that the cost of Li-ion could drop 20% to $80/kWh. When solid state is commercialized it has the potential to bring costs to approximately $65/kWh. This suggests that battery costs have the potential to drop by >40% over the next five years. This equates to thousands of dollars which would make electric vehicles even more affordable.

A Note of Caution

Although solid state batteries sound great, it is important to keep in mind the amount of time and effort it has taken to scale traditional Li-ion electric vehicles. Tesla started production of the Roadster in 2008, Model S in 2012, and Model 3 in 2017. The manufacturing and engineering teams have optimized the production process to increase throughput and dramatically decrease the cost of production. That expertise and industry knowledge is finally spreading to traditional manufacturers such as Volkswagen, GM, Ford, and Nissan. Solid state will experience the same trials and tribulations during the scale-up process, while R&D researchers continue to optimize anodes and cathodes for traditional batteries. Academics and start-ups are evaluating electrolyte additives and elements such as germanium in the anode to enable faster charging/discharging. The question is - who wins? Personally, I feel that solid state will develop a niche market in small devices such as drones and robots, but will have difficulty getting into the electric vehicle space.

References:

Promising Solid State report from October 2020