Sodium Ion Announcement

I cannot possibly ignore the recent news from CATL’s press conference about sodium ion batteries. The Company announced that it is planning to commercialize a new chemistry that will disrupt the current landscape and open up the electric vehicle market.

History

Tesla and Panasonic brought cylindrical lithium nickel aluminum cobalt oxide batteries to mass production in 2012 with the launch of the Model S. Roughly 6-7 years later there were rumblings of LFP (lithium iron phosphate) chemistries entering the market. Naysayers said that the energy density would never be comparable to NMC (lithium nickel manganese cobalt oxide). This is in fact true - LFP has an energy density of ~160Wh/kg and NMC cells have a density of ~250+Wh/kg given the amount of nickel in the material. Despite this, LFP powered electric vehicles are rolling off of Chinese production lines like hotcakes.

In fact, Elon Musk even hinted that LFP has a serious future.

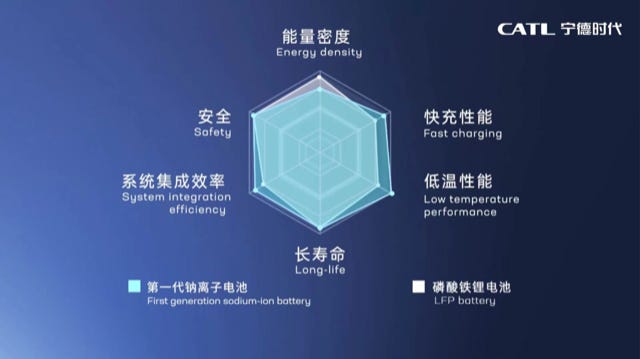

Now, we have the one of the biggest players in battery cell manufacturing touting the sodium ion battery supply chain to be established by 2023. Directly below you can see how the physical specifications compare with LFP. More specs are provided in this Electrive article.

Intangibles and Cost

Although LFP and Na-ion chemistries cannot achieve the energy density of nickel based active material chemistries, they carry unique characteristics that cannot be written with a single stroke of the pen. Both chemistries have significantly better thermal stability and can take faster charge and discharge rates. A common complaint for people living outside of temperate climates is that their electric vehicle could be susceptible to extreme temperatures that inevitably have detrimental impacts on battery performance. LFP and Na-ion can quell that worry.

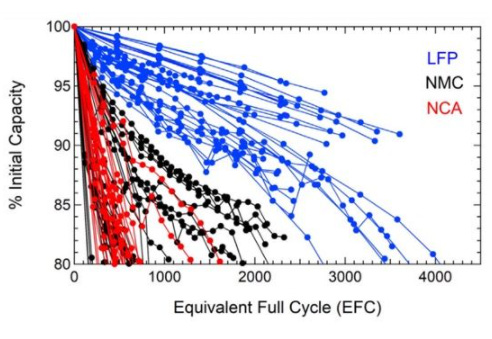

LFP cells can also achieve much longer cycling duration. Which is immensely important for keeping an EV on the road for as long as possible.

An Exciting Future

Full scale commercialization may take a couple more years to bring Na-ion to mass market. Important things such as verifying safety of production line cells/packs will need to be tested in electric vehicles. While the world is scrambling to mine more lithium and other raw materials, sodium ion could introduce a more sustainable option and alleviate global supply chains. The cost of mass produced Na-ion packs will likely be in the $30-40/kWh range, which significantly undercuts Tesla’s goal of $50-55/kWh.