The time has arrived. NMC had its time to shine, but the dynamics of lithium iron phosphate cathode chemistry are too appealing to pass up. The cost, performance, and safety of the LFP blade battery are similar, if not better than commercial NMC batteries.

Introduction

Higher energy density lithium ion batteries typically coinciding with higher Ni content active materials have been pursued for years. Customers’ concerns with range anxiety typically arises around the 300 mile (482km) mark, and battery manufacturers have continually pushed to produce electric vehicles with more range. High nickel materials such as NMC622, NMC811, and NMC9xx seemed like the most logical strategy, because energy density increases in a nearly linear fashion with Ni content.

As a result of optimized fabrication processes, battery management systems, and supply chains the once dead lithium iron phosphate chemistry is making a rise from the ashes. Consumers are finding that the battery supplies adequate range while also providing other performance benefits versus traditional high nickel batteries. In fact, it is gobbling up market share in China-made electric vehicles as we speak.

The market share of ternary layered oxides such as NMC and NCA reached a 90% market share in 2019 and it was projected that they would continue to swallow up demand of the future cathode market. Since the end of 2019, the market share of LFP batteries has gone from nearly 0% to 15% in less than two years. Tight NMC raw material supply and LFP’s lower propensity to combust are the two main drivers that have pushed market adoption.

The LFP Blade Battery

The LFP blade battery is an integral architecture and design that brings substantial innovation to the industry. The thermally modulated LFP blade battery1 provides adequate power, 10 minute fast charge in all climates, and has superior safety compared to other commercially available chemistries.

Let’s dive into the particular metrics that matter.

LFP Battery Performance

The battery provides improvements in all facets including power, charging speed, safety, and cost.

Power

The specific power and peak power density of the LFP blade battery is comparable, if not better than an NMC622 prismatic battery across various states of charge. The power difference is most prominent at lower states of charge suggesting that the LFP blade battery has better performance throughout the entire discharge of the battery.

Charging Speed

Charging speed for traditional electric vehicles is typically measured by how long the vehicle takes to charge from 20% to 80% state of charge (SoC). The Hyundai Ioniq is one of the quickest, taking about fifteen minutes to charge.

The LFP blade battery as shown below enables charging rates nearly double that of an NMC622 battery. C-rates of 10C are possible at 60 degrees Celsius, and it takes just ten minutes to charge from 0% to 80% SoC.

Safety

The thermal stability of LFP is far superior compared to NMC chemistries, especially high Ni (60%+). Extensive work was done by Hanyang University researchers to determine the thermal stability and onset temperature for various active materials. As shown in the image below, the higher the nickel content the lower the thermal stability.

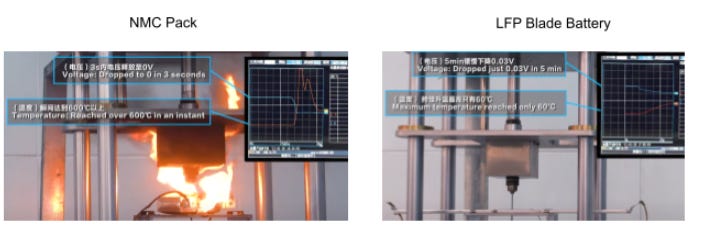

BYD shares a dramatic video of a nail penetration test that shows the nearly instantaneous combustion of an NMC battery pack when the surface is punctured.

Cost

The cost of a lithium ion battery pack is driven by material cost as well as cell integration/fabrication. Lithium iron phosphate active material is inherently cheaper than NMC (nickel manganese cobalt oxide) materials simply based on the abundance of iron. Major battery manufacturers CATL and BYD have taken giant steps forward by supplanting the traditional battery pack design with a cell to pack design. This technology removes the battery modules and enables cells to be directly integrated into a structural pack.

The integration substantially increases the mass and space utilization so that the battery becomes more efficient. The gravimetric cell-to-pack ratio and volumetric cell-to-pack ratio is typically .55-.65 and ~.40 respectively for various commercial electric vehicles. Below is a graphic provided from BatteryBits that helps one visualize the improved space utilization.

The LFP blade battery has been applied to the BYD Han EV enabling it to achieve an outstanding GCTP ratio of .85 and VCTP ratio of .62 which results in significant improvements in energy density.

Given the efficiency improvements of the LFP blade battery it is projected to be less than $75/kWh, which is significantly less than the highest performing NMC and NCA battery packs.

Conclusions:

Tesla set the bar with the original cylindrical cell module and pack design. BYD is rolling out the LFP blade battery in commercial electric vehicles and it is putting significant pressure on the entire market. Not only is the LFP chemistry substantially cheaper than traditional high Ni cathode batteries, but nearly every other performance and safety parameter is improved.

The market is adopting this chemistry and battery design as quickly as possible.

References:

Supplementary Information for LFP Paper

Supplementary Information https://static-content.springer.com/esm/art%3A10.1038%2Fs41560-020-00757-7/MediaObjects/41560_2020_757_MOESM1_ESM.pdf

Noh, H.-J., Youn, S., Yoon, C. S. & Sun, Y. -K.Comparison of the Structural and Electrochemical Properties of Layered Cathode Material for Lithium-ion Batteries. J. Power Sources 233, 121-130 (2013).

Blade Battery Design - BatteryBits. X. Meng. Oct 2020.

Tesla is reportedly going to buy BYD’s new ‘blade batteries’ in an unlikely partnership

Recommended Videos

The Tesla Domain

BYD Global - Nail Penetration Test -