The 4680 Cell

Tesla's push to a larger lithium ion cell.

The cylindrical battery cell has been a major component to Tesla’s success over the years. We are all familiar with cylindrical AA, AAA, and D alkaline batteries that power common household devices such as remote controls, flashlights, and video game controllers. But Tesla raised the bar. In 2008 they released the Roadster which used 18650 lithium ion cells produced by Panasonic, which defined the beginning of a long-term partnership for producing electric vehicles. Tesla relied on Panasonic’s battery cell expertise and production capabilities to guarantee supply as Tesla sought to scale in manufacturing capability over the next decade.

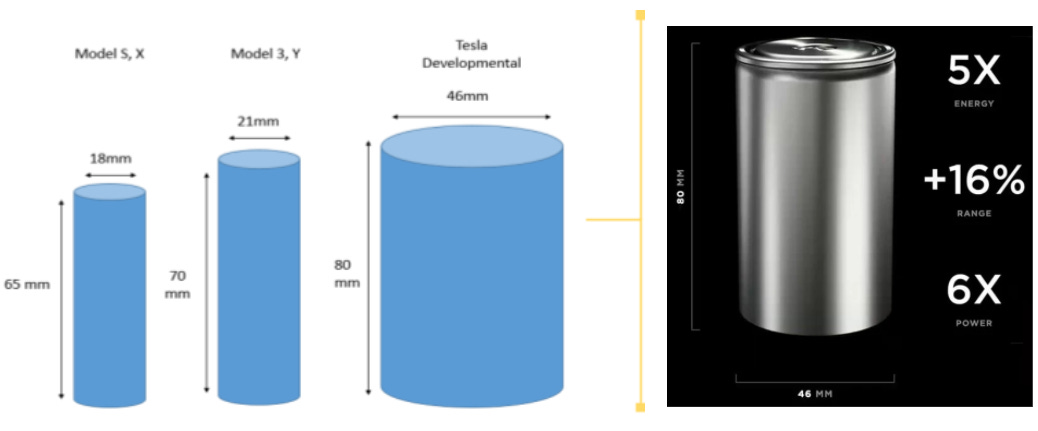

As seen above, the 18650 (18mm x 65mm) was instrumental to the Model S and X, and in 2017 LG Chem made improvements on the cell design by increasing the energy density and capacity with a larger 21700 cell. The most recent Tesla models use these cells, but during Tesla’s Battery Day on September 22, 2020 the company made some striking announcements signaling that it will push the envelope even further. Tesla wants to vertically integrate by producing their own unique battery cells/packs.

The new battery architecture will consist of a 4680 form factor, which will provide significantly more energy and power to future vehicles.

Cell Design History

The original 18650 cells were made of NCA chemistry (Lithium Nickel Cobalt Aluminum Oxide), and the increase in size to 21700 enabled Tesla to increase the energy density and capacity. This enabled engineering and design improvements to improve range and efficiency of the newest Model 3 and Y models.

Let’s first focus on comparing the 18650 and 21700. The increase in cell volume and energy density enables the use of fewer cells to achieve the same battery pack size (kWh). Therefore, this translates into a lower total cell volume and weight, which enables a more efficient battery as seen in the miles/kWh. One would suspect that larger volume of 4680 cells would yield a similar improvement. The 4680 cell brings in a lot of speculation, because Tesla hinted at electrical engineering design improvements making it difficult for us to compare them 1:1 with 21700 cells.

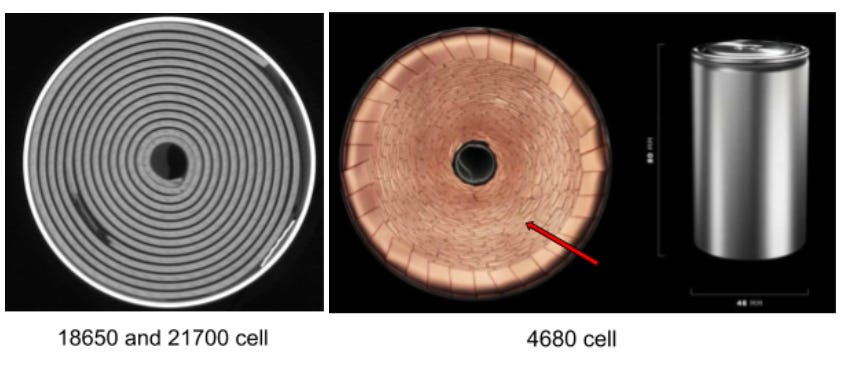

In the below (left) picture you can see an X-ray Computed Tomography Photo showing the uniform winding of a 18650/21700 jelly rolled cylindrical cell. The layers between anode and cathode are clearly defined, but in the proposed 4680 cell it appears flaky and that each layer is interconnected.

4680 Cell Design Predictions

Rather than guessing about exact cell chemistry or electrical engineering, one can be fairly confident on the structural design of the battery module based on existing Tesla models in the market. Although the individual cell is 10mm taller than the 21700 it looks like it will be packed into a simple rectangular design. Elon Musk (below) hinted that the battery pack will be smaller and closer to the center of the vehicle to improve vehicle agility and control.

The cohesive rectangular pack would have an approximate area of 2.03m2 (21.8ft2) and volume of .162m3 (5.72ft3). I superimposed the geometry of the battery (orange) over top of a model 3 displaying area and volume reductions of roughly 6% and 17% respectively.

Efficiency will improve simply based on battery size reduction, but the energy density and total capacity of each cell will determine the pack’s orientation in the vehicle. Tesla summed up their Battery Day discussion saying that the potential cost reductions using the 4680 cell could be 56%. A reduction of this magnitude would surely lower the cost of production to <100 kWh.

Tesla shaped the EV industry, and will continue to drive the lion’s share of innovation. Other EV manufacturers have to rely on major battery producers such as CATL, Panasonic, and LG Chem for supply. If Tesla is able to vertically integrate their new battery cell/chemistry paired with their industry leading software it will be game over for traditional auto manufacturers. Tesla has invested heavily in EV technology for over a decade while the likes of Ford, GM, and Chrysler still have to devote some of their R&D spending to traditional combustion engines. Elon announced a vision for a $25,000 Tesla. We all await the day it is a possibility.

Further Info/Links

1) Tesla Battery Day Highlights - YouTube video below

2) Projections on cost reduction - https://www.tesmanian.com/blogs/tesmanian-blog/tesla-mind-blowing-next-gen-4680-battery-at-56-lower-cost-could-be-70-per-kwh-or-even-lower

3) Why a Tabless Design? https://e-vaahan.com/2020/09/24/how-does-teslas-tabless-cell-design-benefit-them/