Long lasting battery life is important for keeping an electric vehicle on the road throughout its lifetime. Most ICE automobile owners would be happy if they could get 100,000+ miles or at least ten years of operation out of their vehicle. Electric vehicles should be able to last well over 100,000 miles to provide sufficient value for a consumer to make the switch to electric.

Through real world data and driving from many of the earliest Tesla drivers it is apparent that 200,000+ miles is easily achievable with standard wear and tear. In fact, there is a Tesla on the road with nearly ¾ of a million miles.

Solid engineering has enabled the Model S to perform well over many miles. It is unclear what the state of health of the battery is after such long amounts of driving, but I challenge you to find many ICE vehicles that have made it that long without having to fully replace the engine and drivetrain.

What is more fascinating is that the Model S was built on NCA (high nickel) cathodes which have poor long term stability when compared to other cathode chemistries. A couple years ago J. Dahn of Dalhousie University released an open access paper on the “Million Mile Battery”. Data was shared in this paper that clearly demonstrates cycling nearly 4x longer than the typical 1000 cycle benchmark.

The meat of the research was the optimization and design around the LFP cathode chemistry. One drawback of LFP is that capacity and performance significantly declines at cold temperatures (0C). A recent innovation involves coupling that battery with an integrated battery management and software system that enables a thermally modulated LFP battery.

In my previous write-up, Blade Battery Deep Dive, I talk about the significant improvements this battery brings.

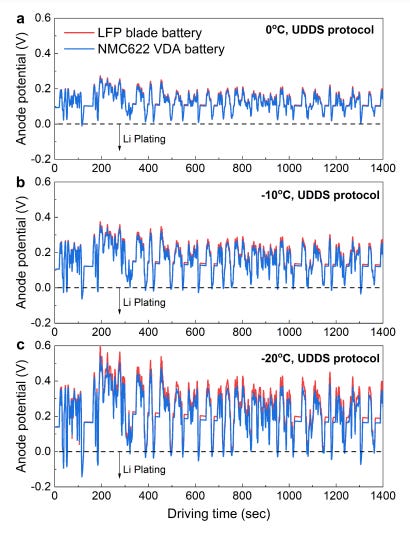

The graph below compares the lithium plating susceptibility of NMC622 and LFP batteries. Plating can occur on the anode when the potential at the anode drops below 0. As temperature drops the rate of plating increases, but the thermally modulated blade actually outperforms the NMC622 battery -20C.

In the next setup, notice how a traditional LFP battery performance significantly degrades at lower temperature. The thermally modulated battery has nearly equivalent performance in three different cold temperature settings, while the NMC622 and standard LFP batteries degrade.

Conclusions:

The thermally modulated LFP battery will be instrumental to the growth of EV adoption. It utilizes LFP, a lower cost active material chemistry, and allows for longer cycling and fast charging capabilities. Cold climates used to be challenging for EVs, and now the thermally modulated design enables a larger potential market for electric vehicle consumers.

References: